Safety glass is a specialized material that enhances building safety by resisting breakage or shattering into harmless fragments. We offer customized solutions to ensure your project meets the highest safety standards

Tempered glass (GB15763.2 standard) significantly improves safety in two ways:

Fragment Safety: When broken, it fractures into small, granular pieces with blunt edges (rather than sharp shards), minimizing injury risks.

Mechanical Strength: Its mechanical strength is 4-5x higher than annealed glass, resisting impacts from wind pressure, hail, and accidental collisions.

⚠️ Note: Semi-tempered glass (non-safety glass) cracks into large sharp fragments and does not comply with safety standards, However, when used as the base layer of laminated glass, it can significantly enhance the strength and make the glass less prone to breakage.

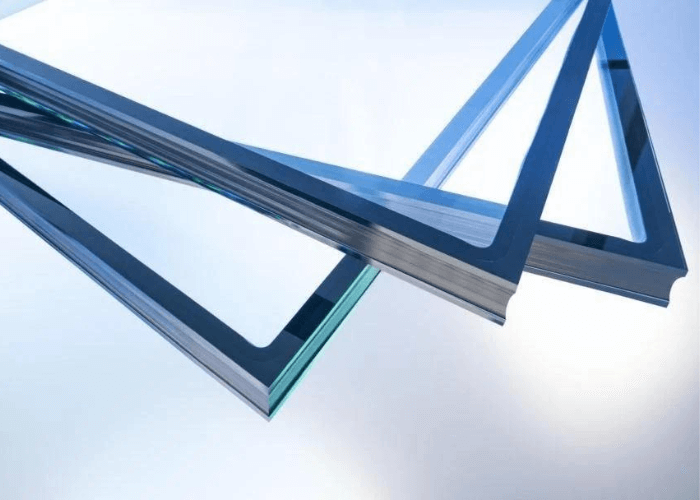

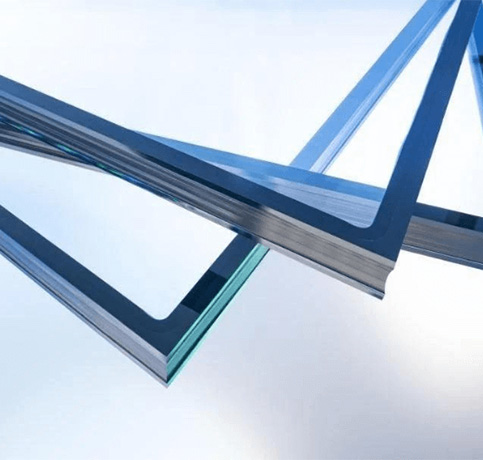

Laminated glass (GB15763.3 standard) enhances safety through: Interlayer Adhesion: Even when shattered, broken fragments remain bonded to the PVB/SGP interlayer, preventing dangerous spalling. (Compared to PVB, SGP interlayer offers greater strength and is suitable for applications such as glass railings or infinity pools)

Anti-Intrusion Protection: Multi-layered laminated glass can be designed for bullet resistance or blast mitigation

✨ Example: Compared to standalone tempered glass, laminated glass reduces post-breakage fall hazards, making it mandatory for skylights and overhead glazing

Impact Resistance: Thicker glass (e.g., 10mm vs. 6mm) withstands higher wind loads and mechanical stresses.

Thermal Stability: Thicker tempered glass tolerates wider temperature gradients (up to 200°C), reducing thermal breakage risks.

Australian Certification: AS/NZS 2208:1996 – Safety glazing materials in buildings;AS 4666:2012 – Insulating glass units

European Certification: EN14449:2015+AC:2005-Laminated glass and laminated safety glass

US Certification: ANSIZ97.1-2015-Laminated Safety Glass;ASTM E2190-Insulating glass unit

Multinational Certifications:ISO9001:2015

The light transmittance and visual effect of safety glass are similar to that of ordinary glass, but the PVB interlayer in laminated glass may slightly reduce transparency.

The initial cost of safety glass is higher than ordinary glass, but its durability and safety make it more cost-effective in the long term.

Laminated glass, with its PVB interlayer, offers superior sound insulation compared to ordinary and tempered glass.

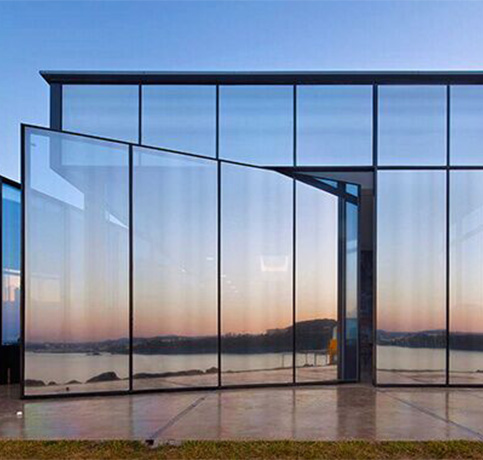

Safety glass can be manufactured in various colors and patterns, and laminated glass can incorporate decorative materials, enhancing the aesthetic appeal of door designs.

Tempered glass thickness typically ranges from 4 to 19mm, while laminated glass ranges from 6 to 19mm. The specific choice depends on design requirements and safety considerations.

Experience the quality of GLASVUE glass firsthand with a complimentary sample tailored to your project requirements.

Let us design a glass solution that perfectly aligns with your unique architectural vision and technical specifications.

Access detailed technical data sheets for GLASVUE’s architectural glass products, including performance metrics and installation guidelines.

Gain inspiration from our curated collection of successful GLASVUE installations worldwide, showcasing innovative applications of architectural glass.

© All Copyright 2024 by GLASVUE | Privacy Policy