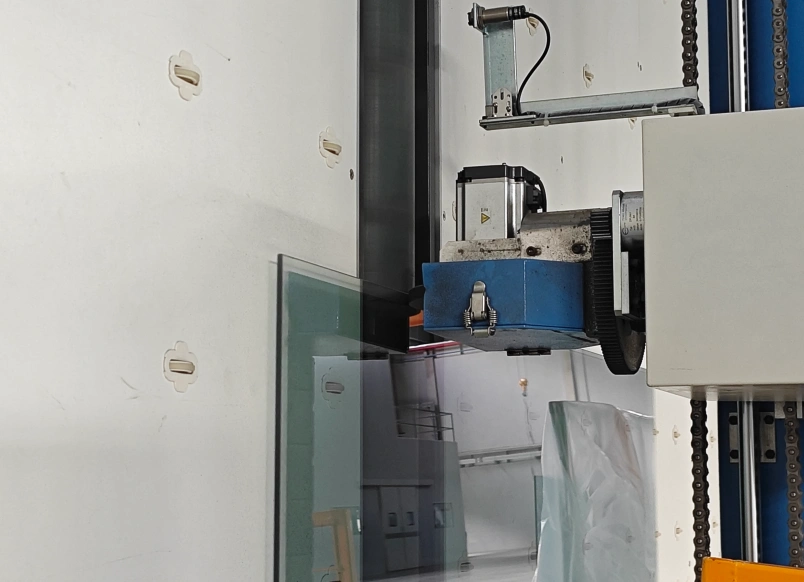

With 29 years of expertise, we specialize in high-performance IGUs for large-scale projects worldwide. Operating from a 20,000+ m² facility with 300,000 m² annual capacity, we offer deep customization in sizes, structures, and substrates like Low-E, ultra-clear, and ceramic frit to meet any architectural requirement.

Certifications

ISO9001:2015 | ASTM E2190 | AS 4666:2012 | GBT11944-2012

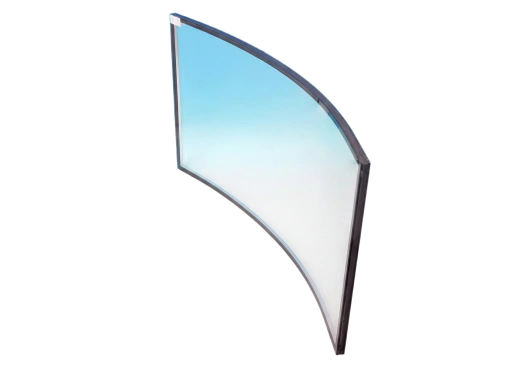

Our insulated glass can be customized with different thicknesses and colors of glass, varying thicknesses of the air space, different types of gases, and more. This ensures that our glass solutions can perfectly meet your specific needs.

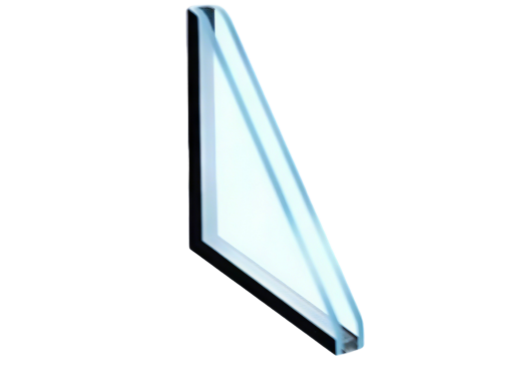

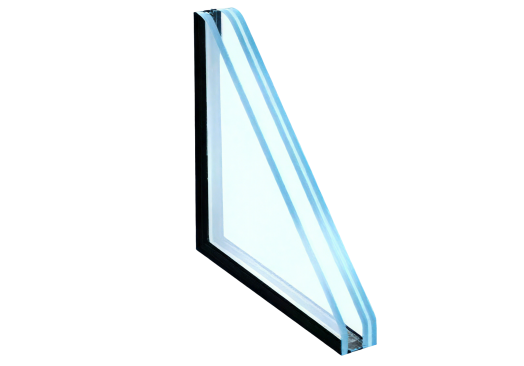

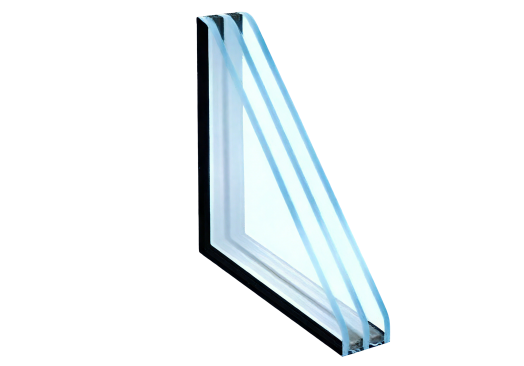

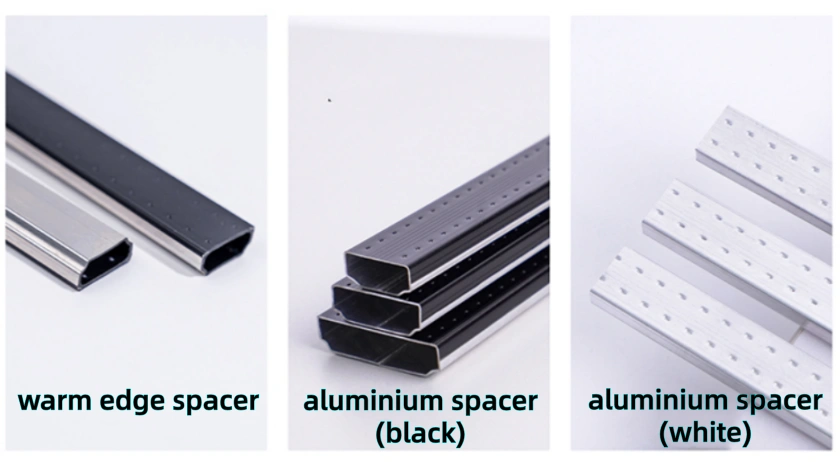

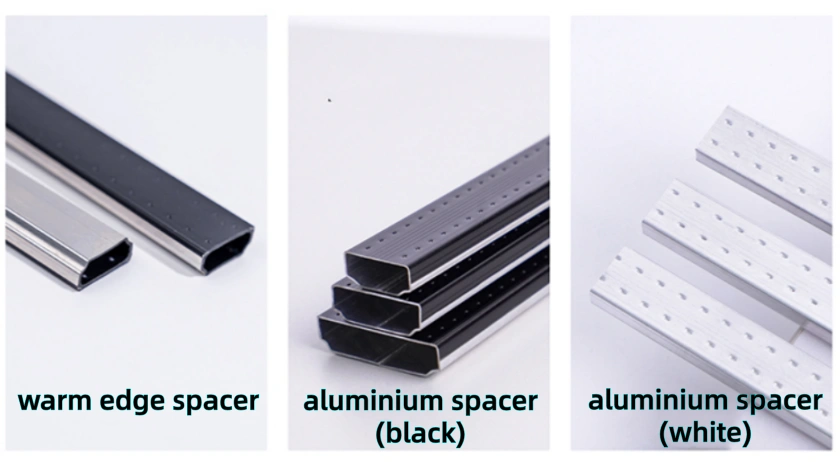

GLASVUE provides a wide range of insulated glass manufacturing services to support all your glass projects and market needs. We offer various types of glass, insulated glass spacers, and insulated glass layers tailored to your specific requirements.

The table below shows the thermal parameters of 6mm Low-E glass + 12A + 6mm float glass.

| Types | VLT | U-Value | SHGC |

| Reflective | 30%-65% | 4.99-5.67 | 0.39-0.67 |

| Single Silver | 35%-71% | 1.73-1.81 | 0.29-0.56 |

| Double Silver | 41%-72% | 1.61-1.64 | 0.22-0.44 |

| Triple Silver | 41%-63% | 1.61-1.66 | 0.21-0.29 |

Insulating glass reduces the glass’s heat transfer coefficient via a dry, sealed air layer, which is much lower than that of a single – pane glass. Its thermal insulation performance can be further enhanced by filling it with inert gas or using low – E glass.

IGUs offer remarkable noise reduction, capable of attenuating sound by approximately 30 decibels. Filling the cavity with inert gas improves soundproofing, particularly for specific frequency ranges.

The sealed cavity of IGUs is filled with dry gas, maintaining minimal water vapor content and a dew point below -40°C. This ensures that IGUs remain resistant to condensation even in extremely low temperatures.

At GLASVUE, in addition to customizing insulated glass based on your specified dimensions and thickness, you can also provide parameters such as external reflective color, light transmittance, and U-value. We will create a tailored glass solution to meet your needs.

Regular insulated glass price range from $2.8 to $18 per square meters. It depends on the actual insulated glass requirements, such as sizes and required specifications. If there is special requirements on more factor like light transmission and more process, it price also rises. You can send us your insulated glass requirements to get an accurate quote. In addition, the buying quantity and logistics costs from China can add to all the cost. You can ask our specialists for help.

The U-value represents the thermal conductivity coefficient of glass, measuring the rate of heat transfer through the glass. The lower the U-value, the better the insulation performance. Generally, the U-value of insulated glass is about half that of ordinary single-pane glass, making insulated glass more effective in retaining heat and saving energy.You can consult our specialists with anything.

Experience the quality of GLASVUE glass firsthand with a complimentary sample tailored to your project requirements.

Let us design a glass solution that perfectly aligns with your unique architectural vision and technical specifications.

Access detailed technical data sheets for GLASVUE’s architectural glass products, including performance metrics and installation guidelines.

Gain inspiration from our curated collection of successful GLASVUE installations worldwide, showcasing innovative applications of architectural glass.